WHT 4

Fully Automated 4-in-1 Tablet Testing Instrument

Test weight, thickness (or height), diameter (or length), and hardness of regular tablets, odd shaped tablets (caplets, oblongs etc.) and other solid samples fully automatically. Use the WHT 4 for the fully automated testing of single tablet critical parameters including weight (in compliance to the European and German Pharmacopoeia for uniformity of mass), thickness, diameter and the tablet hardness also according to the European EP <2.9.8> and USP <1217> Pharmacopoeia.

WHT 4

Fully Automated 4-in-1 Tablet Testing Instrument

Test weight, thickness (or height), diameter (or length), and hardness of regular tablets, odd shaped tablets (caplets, oblongs etc.) and other solid samples fully automatically. Use the WHT 4 for the fully automated testing of single tablet critical parameters including weight (in compliance to the European and German Pharmacopoeia for uniformity of mass), thickness, diameter and the tablet hardness also according to the European EP <2.9.8> and USP <1217> Pharmacopoeia.

Operating Principle

This instrument offers a reliable and reproducible self-contained feeder and measurement station for quality control of samples during tablet production as well as in post-production QC and QA laboratories. The WHT 4 testing system offers four test parameters of the same sample. The instrument is offered as a stand-alone unit including an integrated touch screen PC running the WHT32 software. A single- or multiple-batch feeder may be used to individually file the samples into the testing system for fully automated control of different samples and batches. Using the single feeder WHT 4-SM1 and direct connection to an existing tableting machine is possible. The multiple batch feeder WHT 4-SM is used to test up to 10 different products fully automatically and unattended.

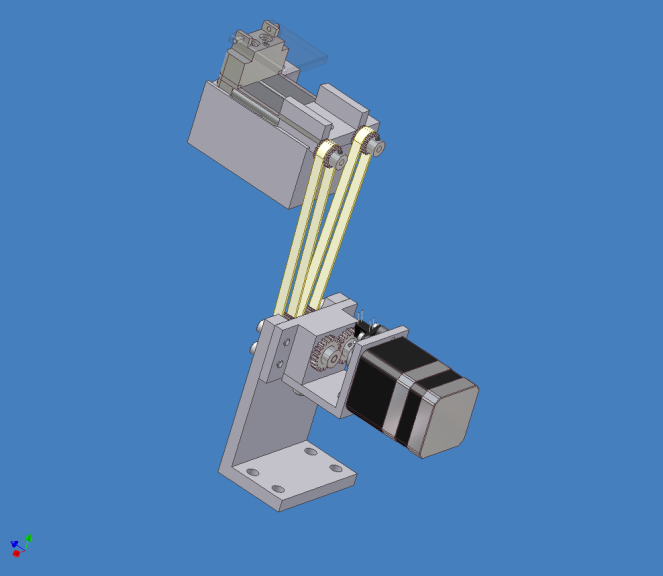

Operation Principle of the Hardness Measurement

The current monographs of the USP and EP Pharmacopoeia define how a tablet hardness testing instrument should work, but without establishing data of how to increase the applied force and when to detect a sample to be broken. This often causes problems when trying to compare results of the same tablet measured with instruments from different manufacturers. The hardness result is directly influenced by the contact speed and force increase rate of testing instrument. A faster operated test jaw means a lower reproducibility and often higher absolute results. In order to offer the possibility to select an operating mode which will offer you similar results to other instruments you may already use, WHT 4 allows to set the force mode by selecting between linear force increase or linear speed increase and the set the force rate. When the instrument detects that the sample has been touched, it switches to the measuring mode and starts to increase the force applied to the sample.

Which Force Mode to Select?

Since more than 10 years ago all Pharma Test tablet hardness testing instruments offer the possibility to select either linear force or linear speed increase. Linear force increase offers the most accurate control, as the rate of increase is directly controlled by the electronic load cell used to read the force. Also it is quite simple to validate the correct and linear operation, as a tablet with, for example 100N hardness, will be broken within 5 seconds, when 20N/s had been set as force increase rate. Linear speed increase can also be used; here the driving speed of the stepper motor is kept linear. Actually, as long as the touching force is kept low, there is not too much difference in the results between the two modes, but validation of this mode is reasonably difficult and requires specific equipment. In general results obtained with the linear speed increase mode are less reproducible than the ones with linear force increase mode. Therefore Pharma Test recommends using linear force increase. We will continue to offer both modes of operation in order to offer the possibility of comparing results of different instruments by setting the same parameters of operation.

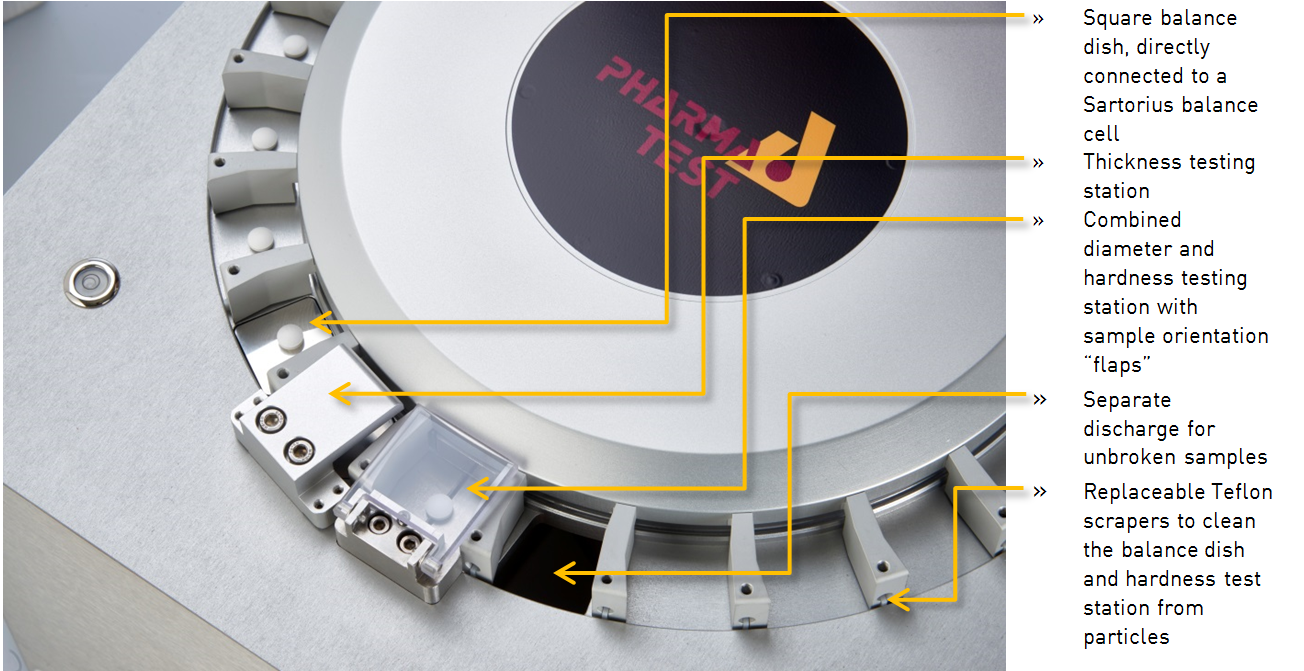

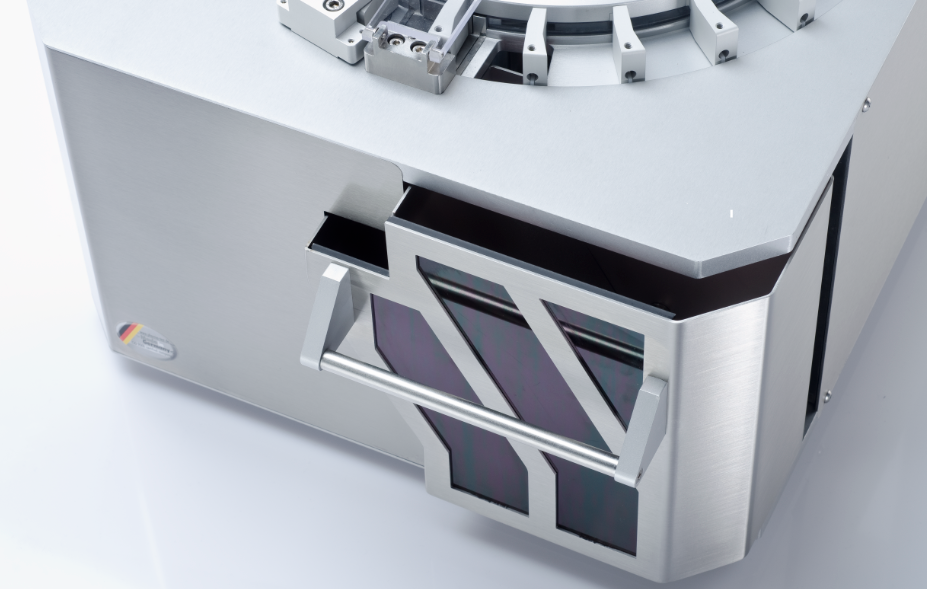

Sample Transportation

For sample transportation a carousel with 20 segments is used. Each of these segments takes one sample. Each segment is equipped with a Teflon scraper to clean the hardness testing jaws from cohesive products and to clean the track of residual particles.

Having a carousel for sample transport, the system can be used without the need of adding a batch feeding system. Simply place one sample into each segment and start the test series. The built-in micro-processor electronics receives the test result from the balance, thickness gauge, load cell and stepper motor and then transfers the information via the RS-232 interface to the WHT32 software program running on the integrated touch screen PC. The PC is connected the main unit by means of an adjustable swivel arm.

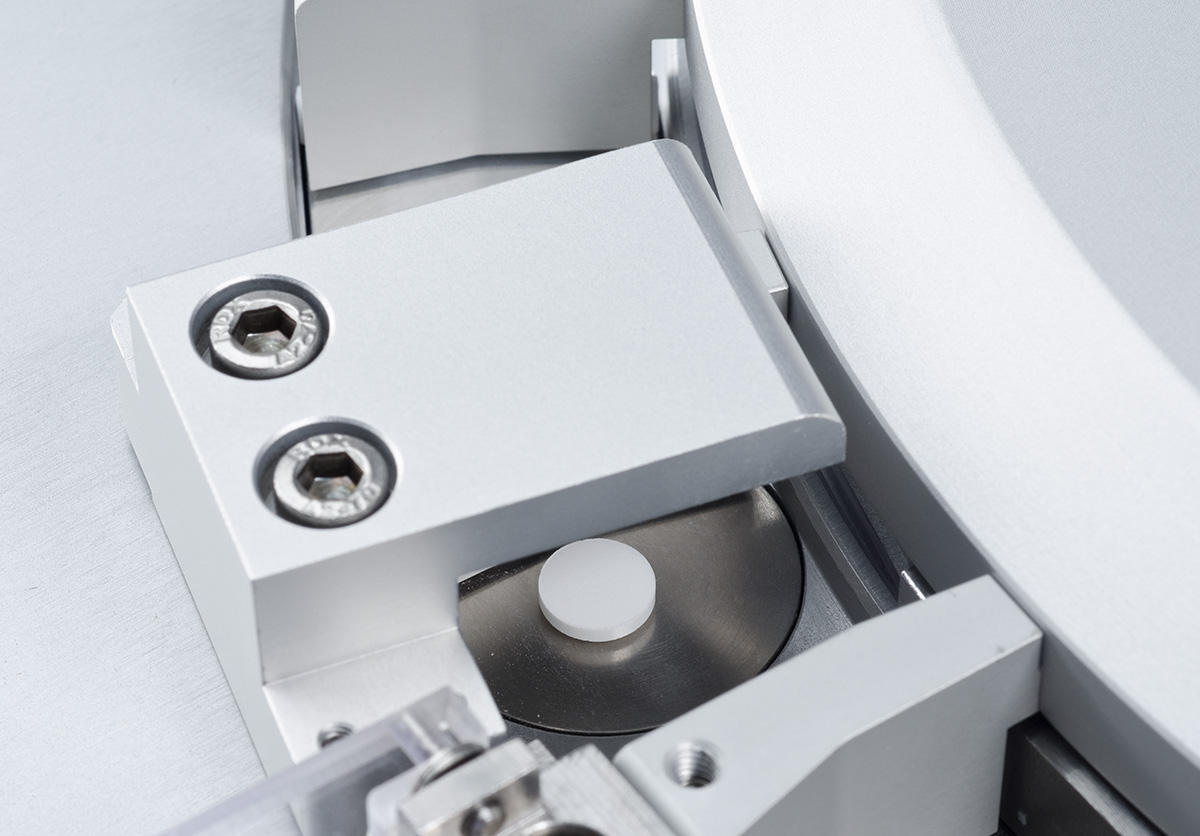

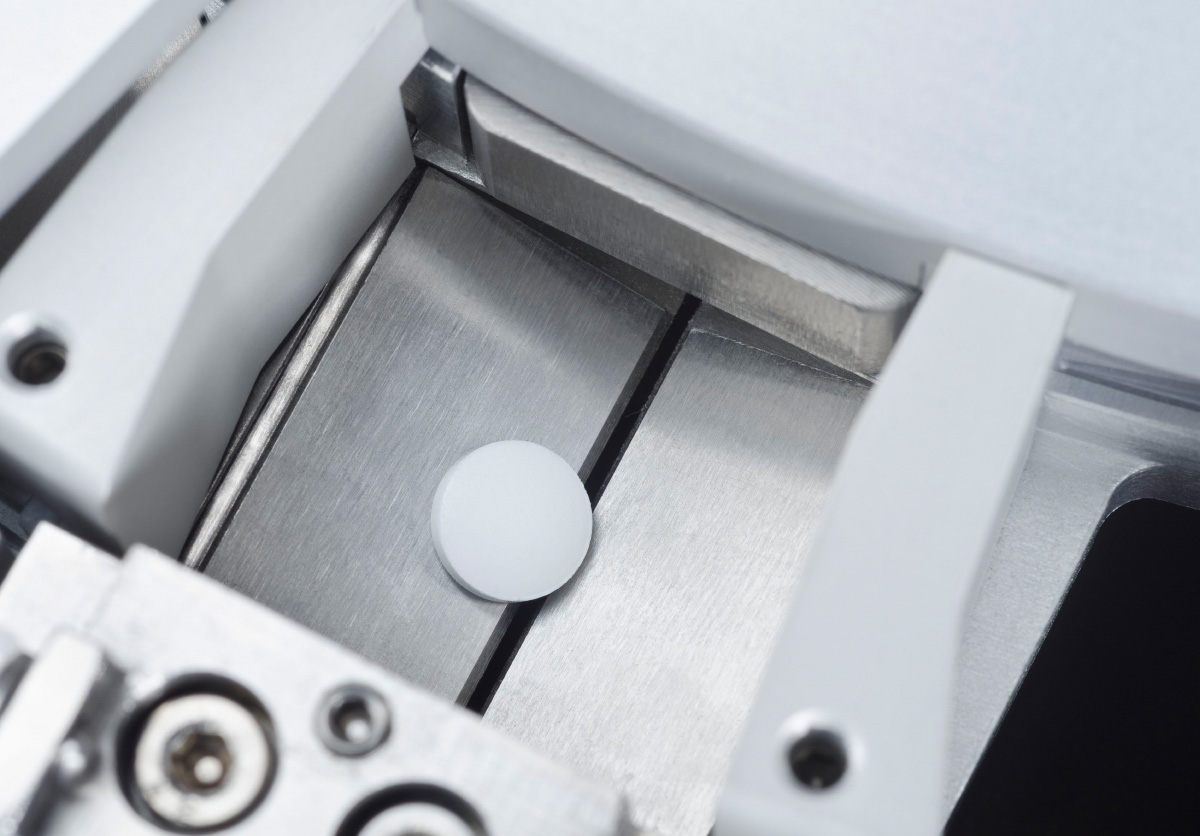

Below on the left the sample transportation from the WHT 4-SM multiple batch feeder into WHT 4 is shown and on the right the unique feature of the WHT 4 is the “flap” device. It positions the sample precisely in the combined diameter and hardness test station.

WHT32 Software Package

The WHT 4 instrument is controlled by the powerful WHT32 software package. WHT32 is available with full 21 CFR Part 11 compliance and includes a methods and results database, validation and calibration programs for all four testing stations, password administration, freely editable print-outs, statistical calculations and graphical print-outs for the performed test run as well as a batch statistical programs. The software is pre-installed on the integrated PC.

Calibration and Adjustment

The current USP Pharmacopeia requires the force sensor of a tablet hardness testing instrument to be calibrated periodically over the complete measuring range (or the range used for measuring samples) with a precision of 1N. All Pharma Test tablet hardness testing instrument can be statically calibrated over the complete measuring range by the use of different traceable counterweights. All instruments support the checking of at least three different points during calibration to prove the linearity of the force sensor.

For the thickness and diameter station, certified reference blocks sets are used for both calibration and adjustment. Weight sets are used to calibrate and adjust the force sensor (load cell) of the instrument over the complete measuring range. For the two point adjustment (zero and reference) of the load cell inside the hardness station a certified reference weight of 10 kg is used. For validation purposes the use 5 up to 50kg certified weights is recommended. The latest calibration and adjustment results are stored on and can be printed and signed. Calibrate the built-in Sartorius balance cell using a 50mg calibrated reference weight.