PTWS 820D

USP/EP Tablet Dissolution Testing Instrument

The PTWS 820D is an 8-position, single drive compact tablet dissolution testing instrument for solid dosage forms as described in USP chapter <711/724> and EP section <2.9.3/4> as well as the DAB and Japanese Pharmacopeia section <15>.

PTWS 820D

USP/EP Tablet Dissolution Testing Instrument

The PTWS 820D is an 8-position, single drive compact tablet dissolution testing instrument for solid dosage forms as described in USP chapter <711/724> and EP section <2.9.3/4> as well as the DAB and Japanese Pharmacopeia section <15>.

User Interface

In keeping with our cutting edge design, a large color, touch screen allows control of the various mechanical features of the instrument such as the tool stirring speed, lift drive and heater. The instrument control is menu driven using a resistive touch screen and selection wheel technology. Visual signals on the display inform the user of the status of critical instrument parameters, e.g. bath target temperature not reached. Access to the instrument can be password controlled if required. If certain operational parameters form a regular feature of the daily routine, then these can be incorporated into a test method for faster set up.

These parameters can be tool speed, target bath temperature, sampling time points and so on. The test method memory capacity is almost limitless. As soon as the test is started, a screen saver can be activated with the most important information displayed in large script so that this information remains visible even at time when the operator is not standing directly in front of the instrument.

Vessel Centering System

The PTWS 820D features a rigid and precise three-point individual centering system for each dissolution vessel (picture shows view from below). The vessels are held in position by three adjustable noses and are inserted into the instrument support framework.

The access points for sampling as well as the openings for the tools are contained in an auxiliary, low evaporation, vessel cover. Each USP Borosilicate glass vessel has a batch code on top of the flange for easy visibility and positioned placement inside the water bath cover.

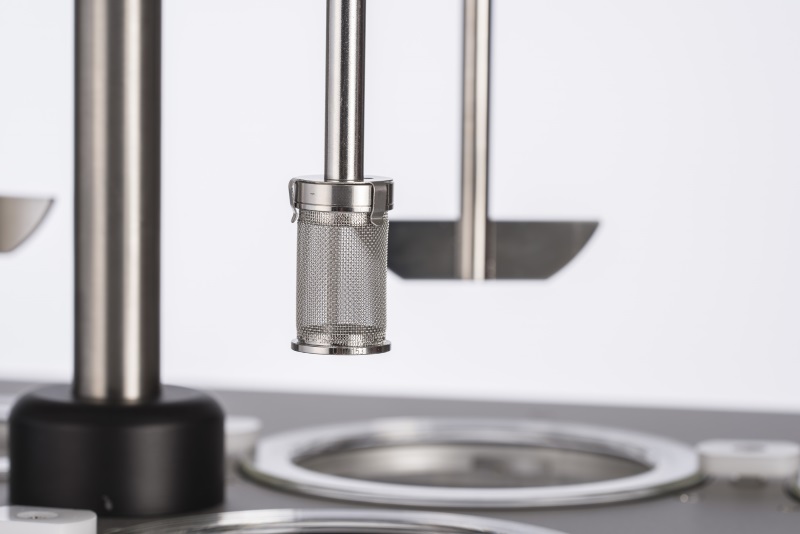

Lift Mechanism

The upper drive is motorized and electronically controlled. It offers eight programmable positions: an upper cleaning and instrument qualification position and lower working positions are programmable depending on the type of stirring tool used. The upper position offers ideal access to the stirring tools and vessels for a change of tools and cleaning steps between the dissolution tests.

The electronically driven lift mechanism is located centrally above the water bath. This ensures that the whole lift drive mechanism is positioned in a way so that the tool shafts are always kept parallel and at a 90° angle to the vessel walls when in the working position.