PTWS 820-MA

8-Position USP/EP Tablet Dissolution Testing Instrument

with Media Addition Station

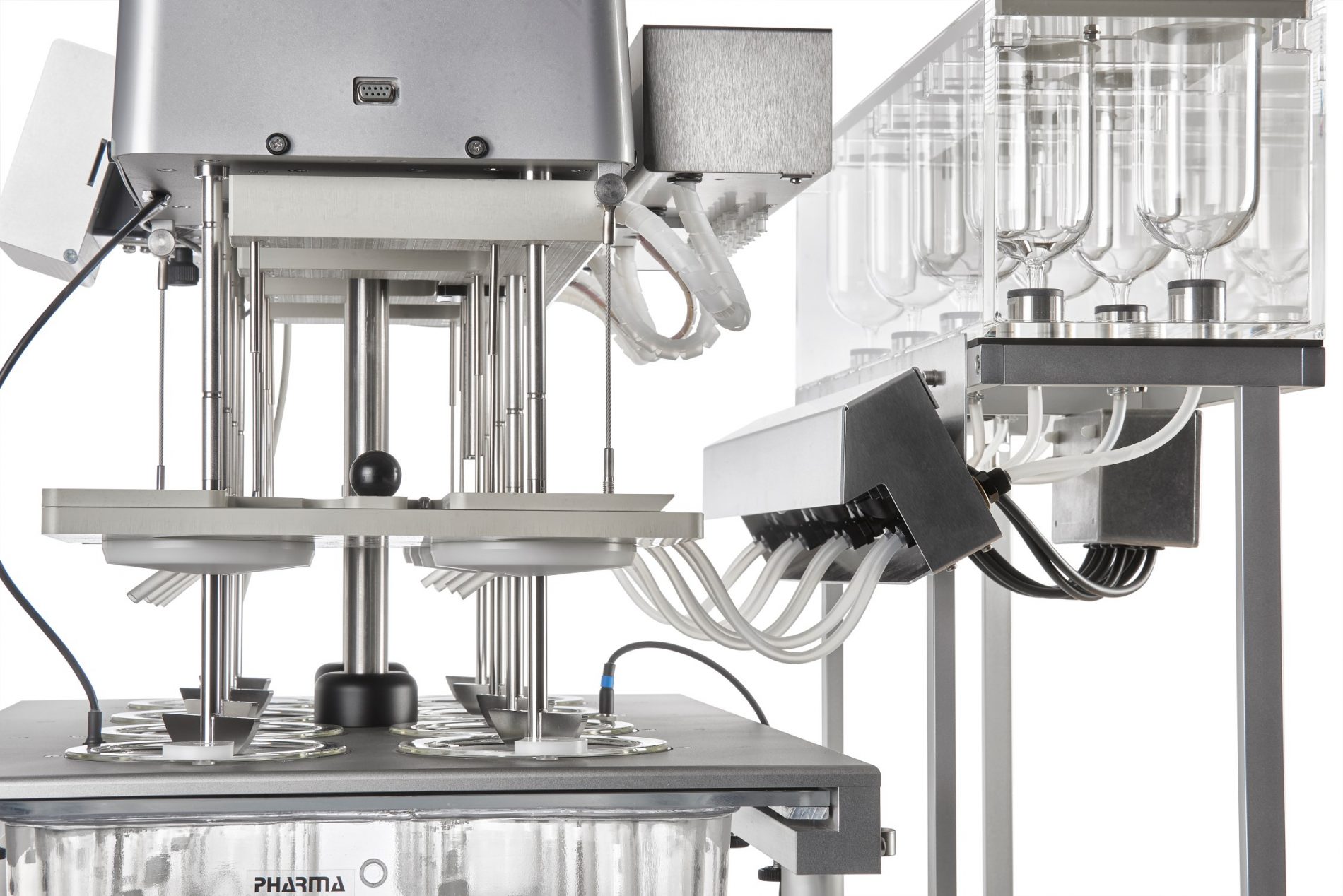

The Pharma Test media addition station PTWS 820-MA together with the PTWS 820D tablet dissolution testing instrument can be used to perform the automated media half change for delayed release dosage forms. The operation is performing according to the requirements from USP <711>, EP <2.9.3> and CP <931> for delayed release dosage forms (in CP, enteric coated dosage forms). The test will start with 750ml of 0.1N HCl. After 2 hours, 250ml of concentrated, pre-heated buffer solution will be dosed quickly into the dissolution vessels. The pH will change to 6.8 and the dosage form should then start to dissolve.

PTWS 820-MA

8-Position USP/EP Tablet Dissolution Testing Instrument

with Media Addition Station

The Pharma Test media addition station PTWS 820-MA together with the PTWS 820D tablet dissolution testing instrument can be used to perform the automated media half change for delayed release dosage forms. The operation is performing according to the requirements from USP <711>, EP <2.9.3> and CP <931> for delayed release dosage forms (in CP, enteric coated dosage forms). The test will start with 750ml of 0.1N HCl. After 2 hours, 250ml of concentrated, pre-heated buffer solution will be dosed quickly into the dissolution vessels. The pH will change to 6.8 and the dosage form should then start to dissolve.

Fully Compliant

Pharma Test has designed the automated media change station PTWS 820-MA which can pre-heat and dose 250ml of concentrated buffer very quickly and simultaneously to the vessels of the PTWS 820D. A heated waterbath is used to pre-heat the concentrated buffer solutions in individual glass vessels. The correct temperature is important, as the amount of liquid added to the vessel is about 250ml. The temperature in the test vessels has to stay within the USP range of 37+/-0.5°C at all times. Therefore the added media should be heated up to 37 °C as well, as the addition of cold media would signifcantly affect the temperature in the test vessels. This way the test can continue immediately as required by USP, CP and EP. It is also possible to operate the whole system via the WinDiss ARGUS dissolution software.