PTB 302 / PTB 502

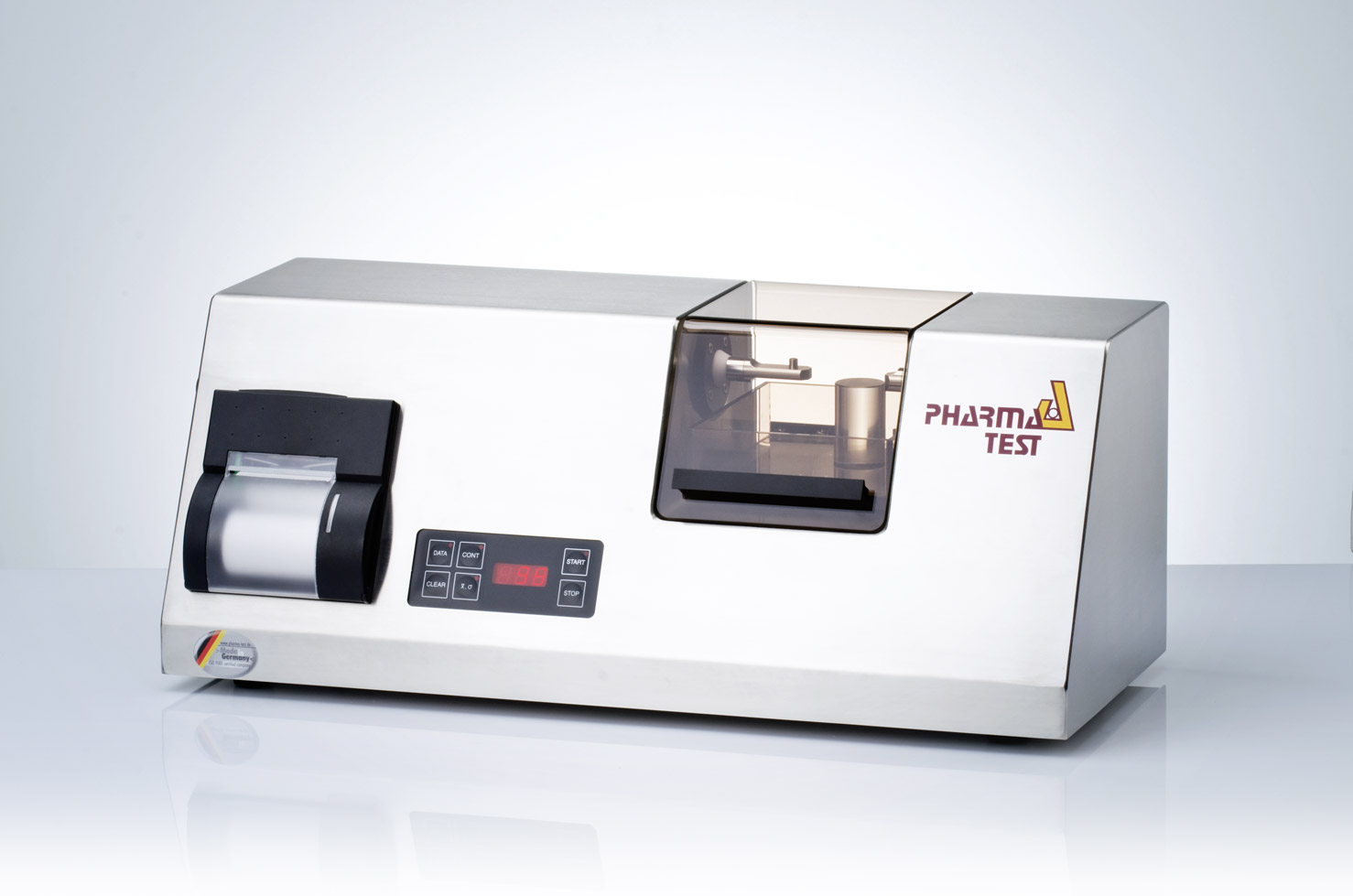

Manual Tablet Hardness Testing Instrument with Integrated Report Printer

The digital tablet hardness testing instrument PTB 302 features an integrated report printer. It is a single force mode hardness test apparatus adjusted for linear force increase while tablet hardness is tested. It offers a multiple point validation procedure for the built-in digital load cell. The instrument is made in strict compliance with the EP <2.9.8> and USP <1217> Pharmacopoeia.

PTB 302 / PTB 502

Manual Tablet Hardness Testing Instrument with Integrated Report Printer

The digital tablet hardness testing instrument PTB 302 features an integrated report printer. It is a single force mode hardness test apparatus adjusted for linear force increase while tablet hardness is tested. It offers a multiple point validation procedure for the built-in digital load cell. The instrument is made in strict compliance with the EP <2.9.8> and USP <1217> Pharmacopoeia.

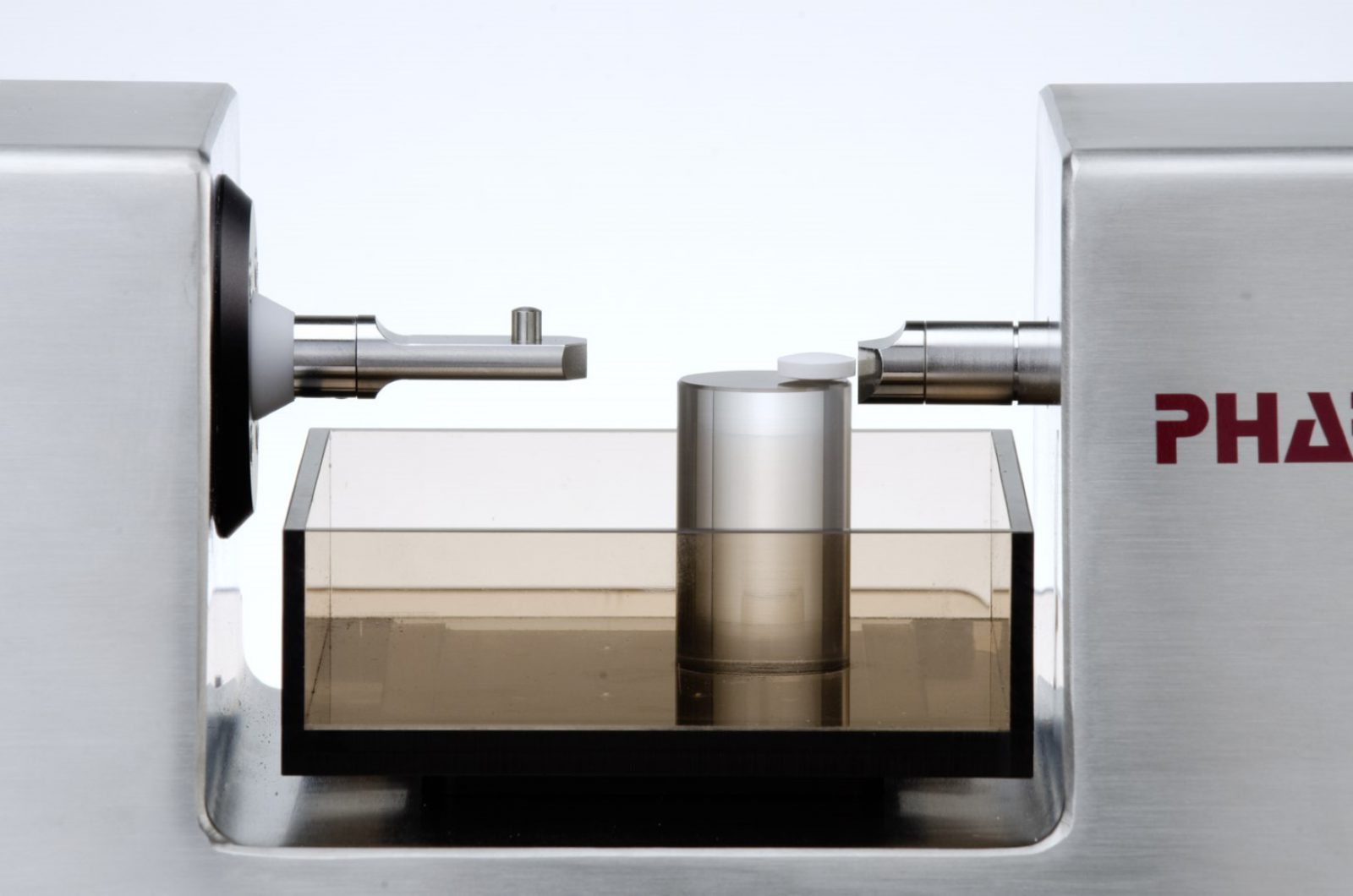

Test Procedure

Select the unit to measure, KP (Kilopond), N (Newton) or Sc (Strong Cobb), now place the sample onto the sample dish and start the test. The driven jaw will run forward, touch and force the tablet until it breaks to measure the hardness (tablet breaking force). No change of tools is required; the design of the jaws does handle most kind of tablet shapes. The result is immediately displayed and printed via the integrated report printer. Repeat this until your series has been tested; get a full print-out including each individual result and an optional block of statistics including mean value and deviations of the test series.

The flexibility and the reproducibility of the results have made this and other models, like the PTB 311E series become one of the most sold tablet hardness testing instruments worldwide. By using an integrated report printer, the bench space requirements to of this instrument are even lower than other instruments from the PTB series, since no additional external printer is required. Furthermore, the report printer requires less paper than a standard printer and by this helps to preserve our precious natural resources.

Operating Principle

Even in the existing USP and EP monographs there is no standard force setting or force increase mode established, but it is recommended to use a linear force increase rate of 20N/s. Different force settings usually cause problems when comparing results received by different supplier’s instruments when testing the same tablet. The hardness result is directly influenced by the contact speed and force increase rate. Faster operated test jaw means lower reproducibility and often higher results.

Linear Force Increase

For more than 20 years all Pharma Test hardness testing instruments offer the possibility to select a linear force increase rate. Linear force increase is the recommended setting as it offers the most accurate control, as the rate of increase is directly controlled by the electronic load cell used to read the force. Also it is quite simple to validate the correct and linear operation as a tablet having a hardness of 100 Newton will be broken within 5 seconds if 20N/s had been set as force increase rate. The test of “soft” tablets often requires an increase of the standard force rate setting otherwise the sample gets deformed only but does not break. To select a linear speed increase mode is impossible using the PTB 302/502 hardness test instrument.

Calibration and Validation

The current USP Pharmacopeia requires the force sensor of a tablet hardness testing instrument to be calibrated periodically over the complete measuring range (or the range used for measuring samples) with a precision of 1N. All Pharma Test tablet hardness testing instrument can be statically calibrated over the complete measuring range by the use of different traceable counterweights. All instruments support the checking of at least three different points during calibration to prove the linearity of the force sensor.